After adding Direct Causes, navigate to Improvements on the left side of the page.

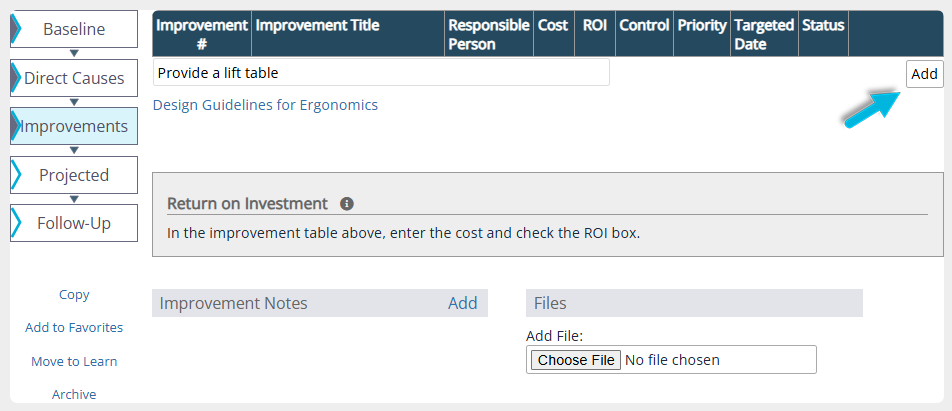

Add a brief description of your improvement idea by typing it into the “add a new improvement” box. Then select Add or press Enter.

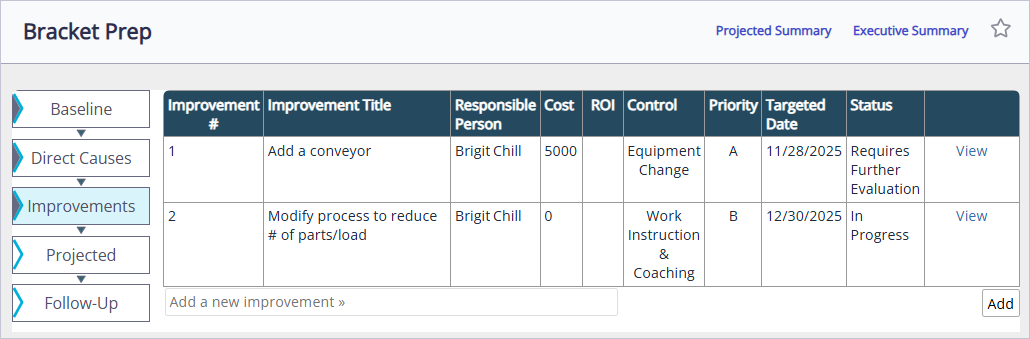

The description that you entered in the “add a new improvement” box will become the improvement title. To edit your improvement and add additional information, select View on the right side of the table.

As you work through the improvements for this job, you will likely visit this Improvements page multiple times to update them.

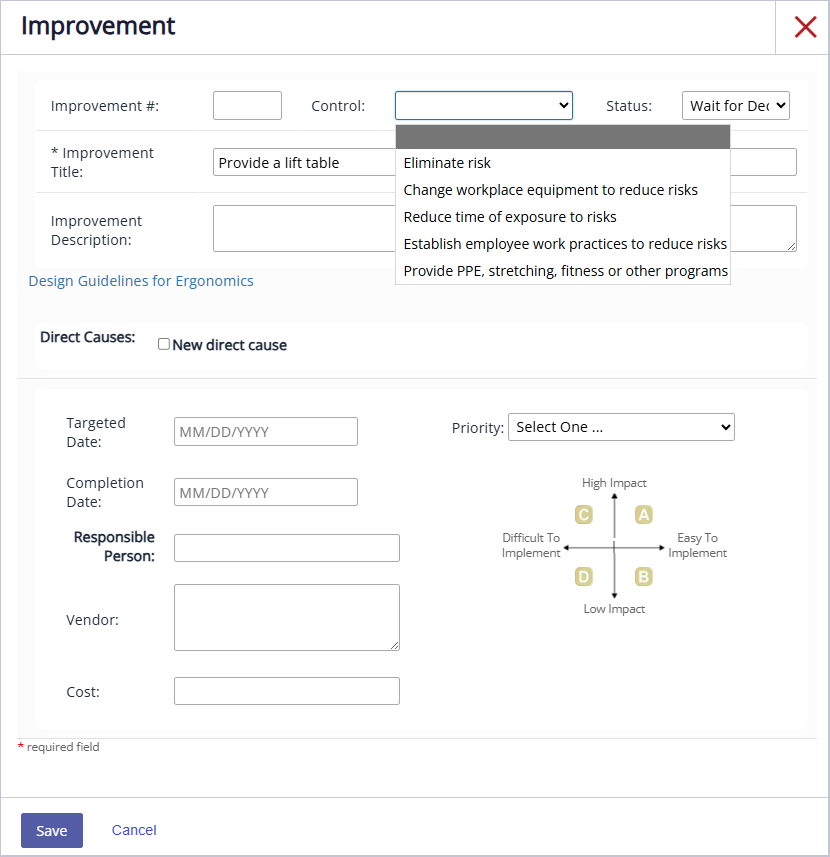

- The Control category lets you assign a rating based on the hierarchy of controls. For more about the hierarchy of controls, see What is the hierarchy of controls?

- Use the Improvement Description to provide the specifics of your improvement and how it would benefit operators. We recommend including details like product dimensions, required safety features, etc. For tips, see Writing Improvement Descriptions.

- Select the Direct Cause(s) that this improvement is addressing (from those already defined for the job assessment). For more about direct causes, see Adding Direct Causes to an Advanced Whole-Body Assessment or Completing a Job Assessment Using the Manual Whole-Body Assessment.

- The Status of an improvement defaults to Wait for Decision. As you make decisions about improvements, you can change this status to accurately reflect your progress. The Improvement Plan Summary page shows the distribution of these statuses. Note that an improvement status affects the status of any linked direct cause as described below.

Status Description Wait for Decision Not yet approved. Updates the status of any linked direct cause to In Progress. In Progress Scheduled/ordered and all approvals are complete. Updates the status of any linked direct cause to In Progress. Completed Implemented and all training/documentation is complete. Updates the status of any linked direct cause to Addressed. Requires Further Evaluation Requires evaluation for feasibility, or multiple alternatives are still being reviewed. Updates the status of any linked direct cause to Not Addressed. Not Feasible Not feasible and will not be implemented. Updates the status of any linked direct cause to Not Addressed. Planned Hold To be revisited (usually at least 6 months in the future). Updates the status of any linked direct cause to Not Addressed. - The priority matrix is divided into four sections based on impact and implementation efforts. To select a priority level in this matrix, use the drop-down menu or click on the graph. Generally, for an improvement to be considered high impact, it should eliminate or significantly reduce risk for body areas with high or moderate risk levels. For an improvement to be considered easy to implement, it should take fewer than 6 months and cost less than $3000 to implement.

Note: These qualifications may differ across different organizations. Talk with your local site administrator to discuss what qualifications your company uses to classify priority categories.

As you progress with the improvement over time, you will be able to add information about it on this page such as the Targeted Date, Completion Date, Responsible Person, Vendor, and Cost.

On the main Improvements page, you can add notes in Improvement Notes to log information like purchase order numbers, maintenance request numbers, etc. You can also use the Files section to upload multiple files (product images, CAD or design drawings for equipment, etc.).

For information about using the Return on Investment calculator, see Calculating Return on Investment for Proposed Improvements Using the ROI Calculator.

Managing Tasks Associated with Improvements

There may be many subtasks to be completed throughout the process of implementing an ergonomics improvement. But how will you document and track them all?

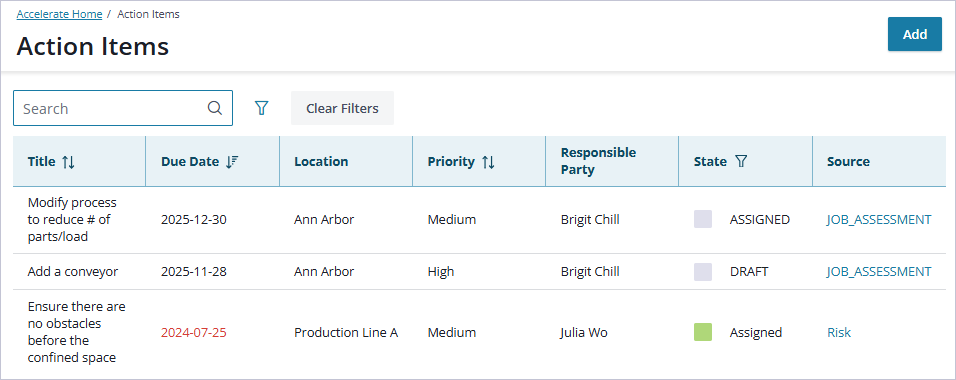

When you assign a Responsible Person to an improvement, an action item is automatically created in Accelerate Action Management, for visibility and monitoring. To access the Action Items page in Accelerate, select Platform > Action Management.

Note: You can see only action items you’ve created or that are assigned to you on this page.

From this page, the designated Responsible Person can select the action item to go directly to the improvement associated with it to view or update it.

Changes made to improvements are kept in sync between the job assessment record and the Action Items page, which reflects updates at key moments in the life of the improvement (when it’s assigned, when the status or priority changes, becomes overdue). For example, when a Responsible Person marks an improvement complete in a job assessment, the related action item on the Action Items page reflects that status change.

For reference, the following tables map the Status and Priority designations in each area.

| Improvement Status | Accelerate Action Item State |

| Wait for Decision | Draft |

| In Progress | Assigned |

| Completed | Completed |

| Requires Further Evaluation | Draft |

| Not Feasible | Completed |

| Planned Hold | Assigned |

| Improvement Priority | Accelerate Action Item Priority |

| A | High |

| B | Medium |

| C | Medium |

| D | Low |