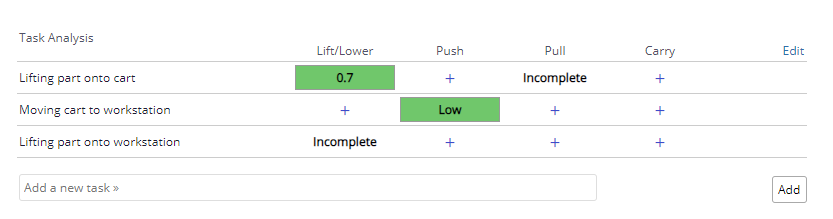

The Manual Material Handling Tasks List (Task Analysis section) in the Baseline and Projected phases of a job assessment applies to single-person, two-handed tasks and is used to assess the risk of lower back injury.

Based on your entries in this section, the software calculates a quantitative (NIOSH Lifting Index) or qualitative (Low, Moderate, or High) risk rating for each task. You can use these results to determine safe lifting/lowering or material handling improvement recommendations.

You can use the Task Analysis feature with both Advanced and Manual Whole-Body Assessments to record a variety of measurements associated with the assessment. Using this section to record weights and/or forces is especially important when using the Advanced Whole-Body Assessment since the application cannot determine weight or force from the video.

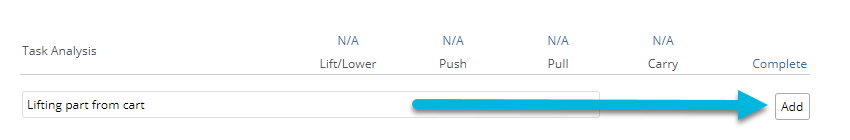

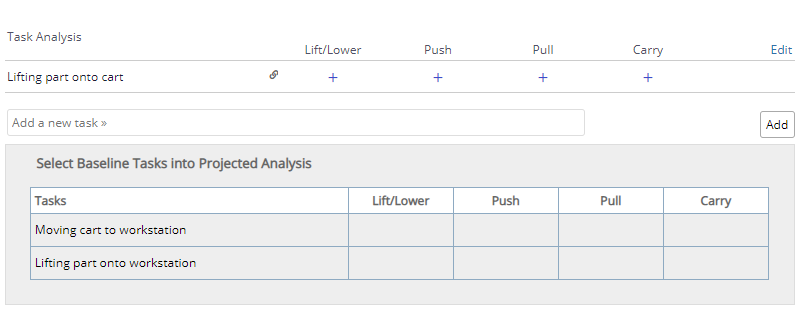

Adding a New Task

Once you’ve created a job assessment that includes a single-person, two-handed task, locate the Task Analysis section in the Baseline phase.

Enter the name of the task in the Add new task field and select Add.

You can add up to 20 tasks per job assessment.

To change a task name, select the task from the list and enter a new name. The change saves automatically.

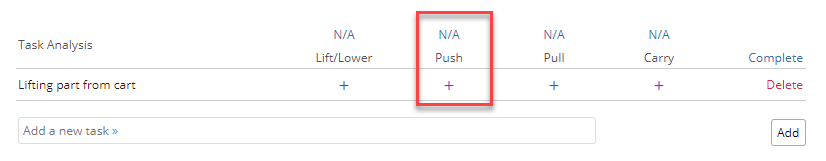

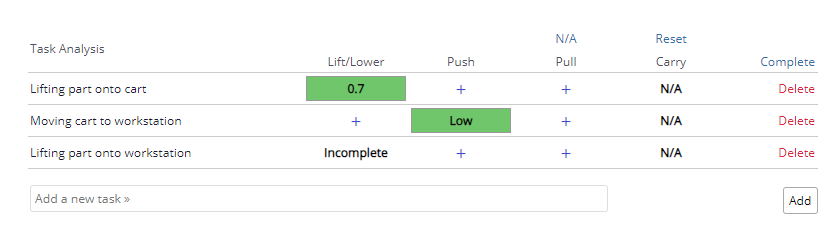

If an analysis does not apply to this task, select the N/A option above the analysis name.

Select the + symbol for the analysis you wish to perform.

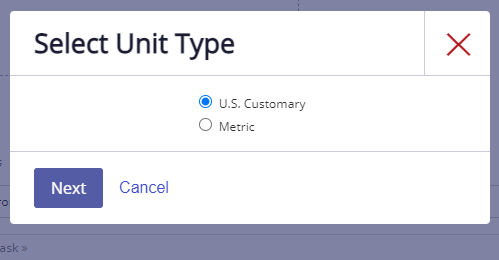

Select the Unit Type. Select Next.

Note: When a measurement is between two options for distance, hours, or frequency for any of the manual material handling analyses, select the more extreme option so that you do not underestimate the risk associated with the task.

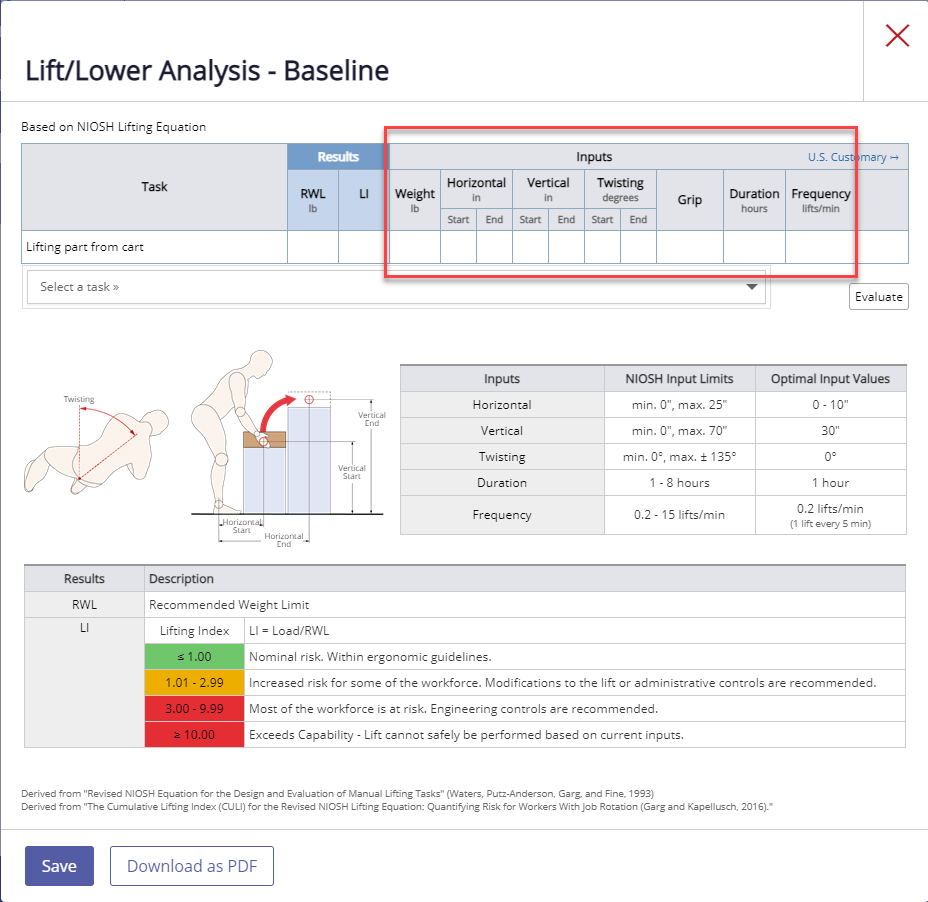

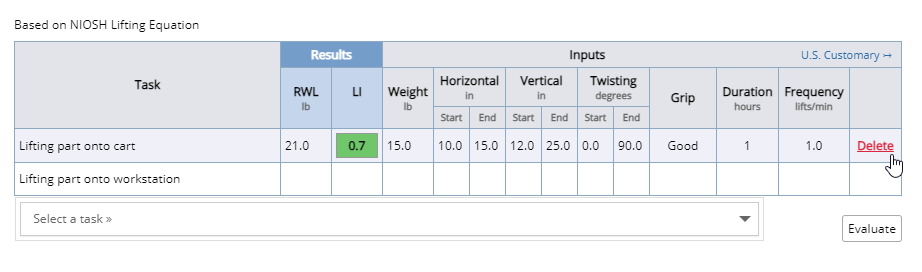

Lift/Lower

If the operator lifts or lowers any item weighing 10 lb or more during a job task, use the NIOSH Lifting Equation to calculate the associated risk. To collect the appropriate measurements, have the operator hold his or her position when first picking up the item, and also when setting it down in the end location.

Enter each of the variables and then select Save.

Following are the required inputs and information on how to collect measurements for each of these variables.

To add additional tasks from this page, click the Select a task field and enter another task name.

When you have entered all required inputs, the risk rating results display.

- Weight of the item being picked up or moved.

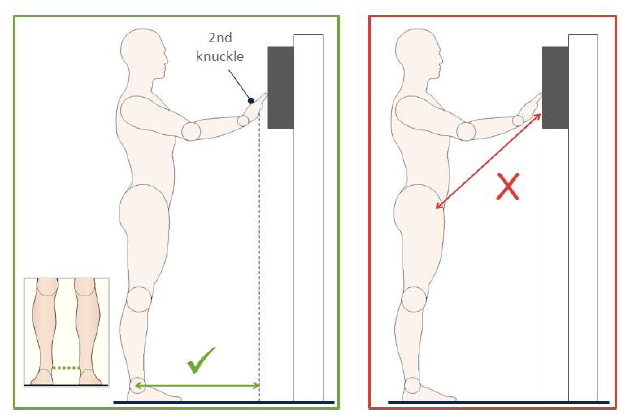

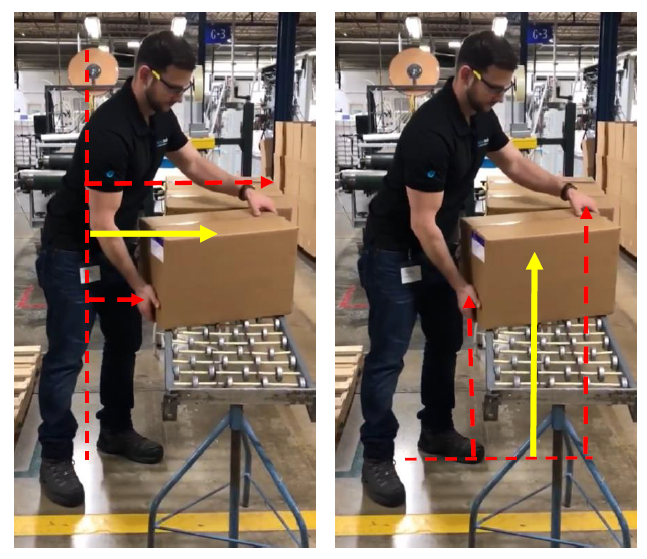

- Horizontal distance: measured (with tape measure parallel to the floor) from mid-point of the ankles to the middle-finger knuckle of the hand. Record this measurement when picking up the item (start of lift/lower) and when setting it down (end of lift/lower).

- Vertical distance: measured (with tape measure perpendicular to the floor) from the standing surface to the middle-finger knuckle of the hand. Record this measurement when picking the item up (start of lift/lower) and when setting it down (end of lift/lower).Tip: Take all horizontal and vertical measurements with the tape measure parallel and perpendicular to the floor surface, respectively, never at an angle.

Tip: If the feet or hands are staggered, take the horizontal and vertical measurements from the midpoint between the two.

Tip: If the feet or hands are staggered, take the horizontal and vertical measurements from the midpoint between the two.

- Twisting: angle away from the body’s midline, based on the relationship between the shoulders and hands relative to the feet. Record this measurement when picking the item up (start of lift/lower) and when setting it down (end of lift/lower).To measure twisting, place a goniometer or protractor on the floor; place one arm of the protractor in line with where the torso is pointing and the other arm of the protractor in line with where the toes are pointing. Twisting is two static measurements of the angle between the shoulders and the feet at the beginning and end of a lift. It is not the distance through space that the operator rotates the body.

- Grip: refers to how the operator holds the item, and it can fall into one of three categories:

- Good: The operator uses a power grip to hold the item. Handles or hand cutouts are available on the item, and the weight is evenly distributed.

- Fair: The operator uses a pinch grip or finger press to hold the item, and the weight is evenly distributed.

- Poor: The grip is considered poor for irregular objects that are bulky or hard to handle and that don’t allow for even weight distribution.

- Duration: hours per day the operator spends performing this lifting/lowering task.

- Frequency: how many lifts the operator performs per minute during the task.

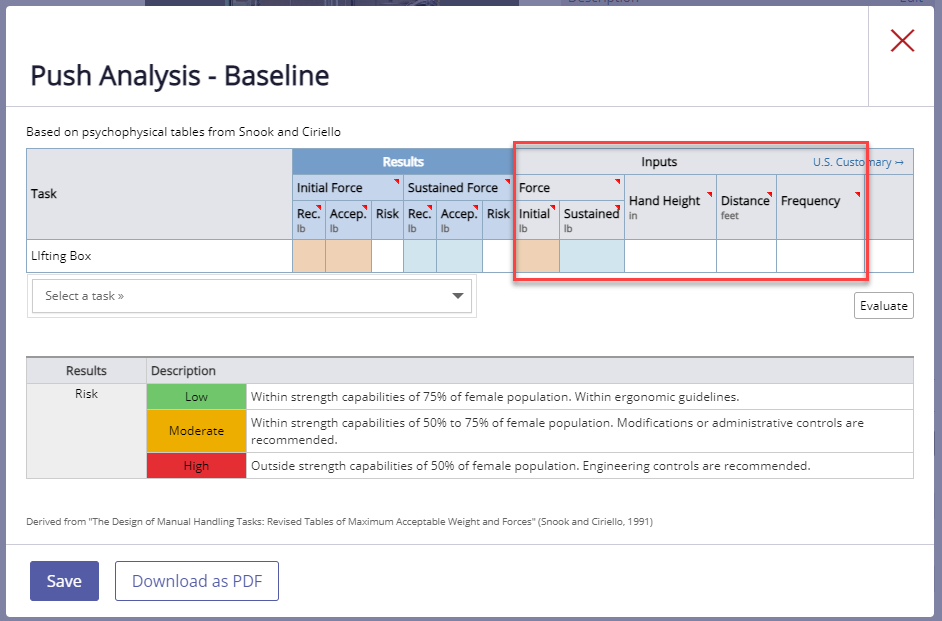

Push/Pull

If the operator performing the task pushes or pulls an item while physically traveling a distance with that item (walking), collect data for a push/pull analysis. Sliding objects across a surface is not considered a push/pull for this analysis.

To add additional tasks from this page, select the “Select a task” field and enter another task name.

When you have entered all required inputs, the risk rating results display.

A force gauge is required to collect the following measurements for a push/pull:

- Initial Force: the amount of force it takes to get the item moving. Set the force gauge to peak or max mode.

- Sustained Force: the amount of force it takes to keep the item going once in motion. Set the force gauge to tracking or normal mode.

- Hand Height: where the operator’s hands are positioned when interacting with the object being pushed or pulled. Select the option (chest, forearm, or thigh) closest to the actual position.

- Distance: how far the operator pushes or pulls the item.

- Frequency: how often the operator performs this push/pull task during a shift.

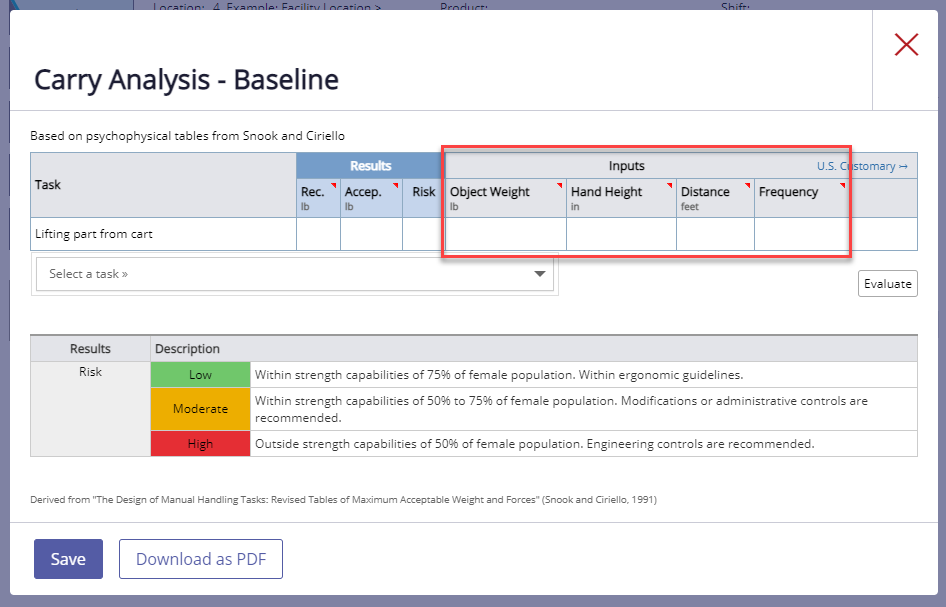

Carry

This equation applies if the operator performing the task carries an item a distance of at least 7 feet.

To add additional tasks from this page, click the “Select a task” field and enter another task name.

When you have entered all required inputs, the risk rating results display.

- Object Weight: weight of the item.

- Hand Height: where are the operator’s hands are positioned when carrying the item. Select the option (elbow or hand) closest to the actual position.

- Distance: how far the operator carries the item.

- Frequency: how often the operator carries the item during a shift.

Editing a Task

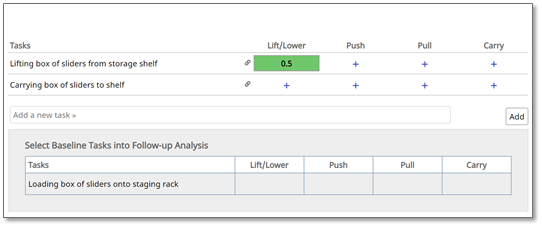

Once you’ve completed all required inputs and returned to the Baseline job assessment, the Task Analysis list displays the quantitative (Lifting Index) or qualitative (Low, Moderate, High) risk rating. If the equation produces two qualitative risk ratings, such as for a push or pull analysis, the higher of the two risk ratings (initial or sustained) appears in the Task list.

Select a risk rating to adjust inputs.

A task listed as Incomplete means that all required inputs have not been entered. Select “Incomplete” to enter them.

To delete a task or remove the N/A designation, select Edit.

Use Reset to remove the N/A designation.

Use Delete to delete the task.

Note that you cannot delete a task until all associated analyses have also been deleted. To delete analyses, select the risk rating or “Incomplete.” Then hover over the task item and select Delete.

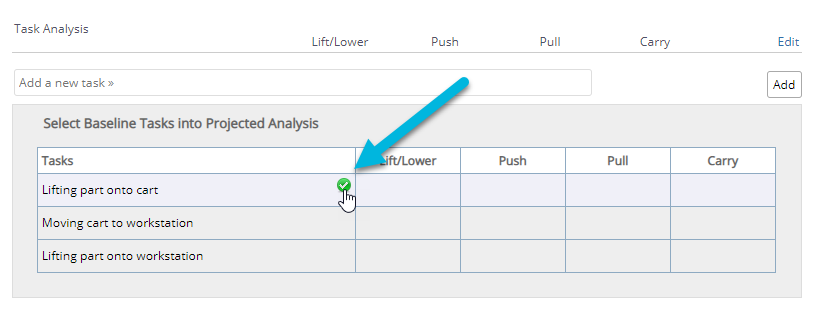

Adding Tasks to the Follow-Up or Projected Phase

If a new manual material handling task is introduced into the job as a result of modifications, follow the steps above for completing the analysis for that task in the Projected and Follow-Up sections.

If a task is still present in a job after analysis and improvement or is affected by improvements, copy the task name from the Baseline analysis to a Follow-Up Analysis to link the two, and update it as needed.

To copy a task:

- Open the job assessment to which you want to add a Follow-Up or Projected manual material handling analysis.

- In the Tasks list, hover over the task and select the green check symbol next to the task name you want to copy.

- Once the task is copied, follow the same steps as above to complete the analysis.

Tip: If a lift/lower task is eliminated from a job as a result of an improvement, copy the task name, but keep all input values the same while adjusting the weight to zero. This will allow the system to track the risk reduction associated with eliminating the lift/lower task.

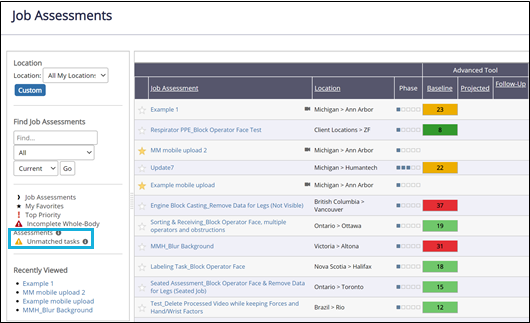

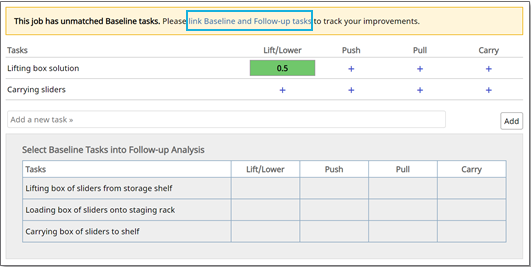

Resolving Unmatched Tasks

To find assessments with unmatched follow-up tasks that need to be updated

(i.e., baseline and follow-up tasks that are related to each other are not linked), go to the Job Assessments page in the Do section. Select Unmatched tasks to filter by this category.

- Open the job assessment that contains unmatched follow-up tasks. Select Follow-Up at the left side of the page.

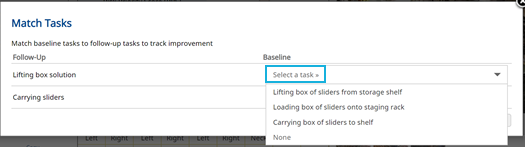

- Select link Baseline and Follow-up tasks to display a list of unmatched follow-up tasks.

- From the Select a task >> drop-down, select the corresponding baseline task for each unmatched task, and then select Merge.

- The name of the follow-up task will update to the baseline task name you just selected, and the link symbol displays. If input variables were already entered for the follow-up task, they will remain unchanged. Once you have resolved all unmatched tasks, the notification box no longer displays above the Tasks list.

Note: Even if a manual material handling task remains unchanged as a result of implemented improvements, the tasks and corresponding input variables should be transferred to the follow-up assessment to maintain an accurate record of risk associated with the job task.